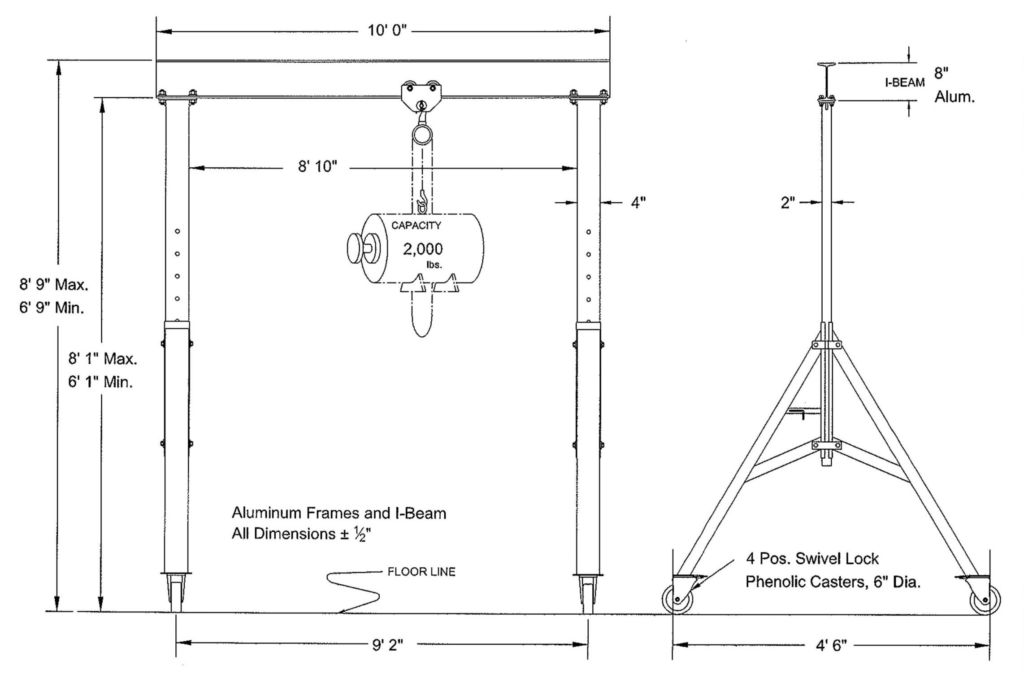

Model A28-10AC

Thrifty Aluminum 1-Ton Gantry Crane

10′ Span, 6′ 9″ – 8′ 9″ Adjustable Height

✓ Aluminum Construction

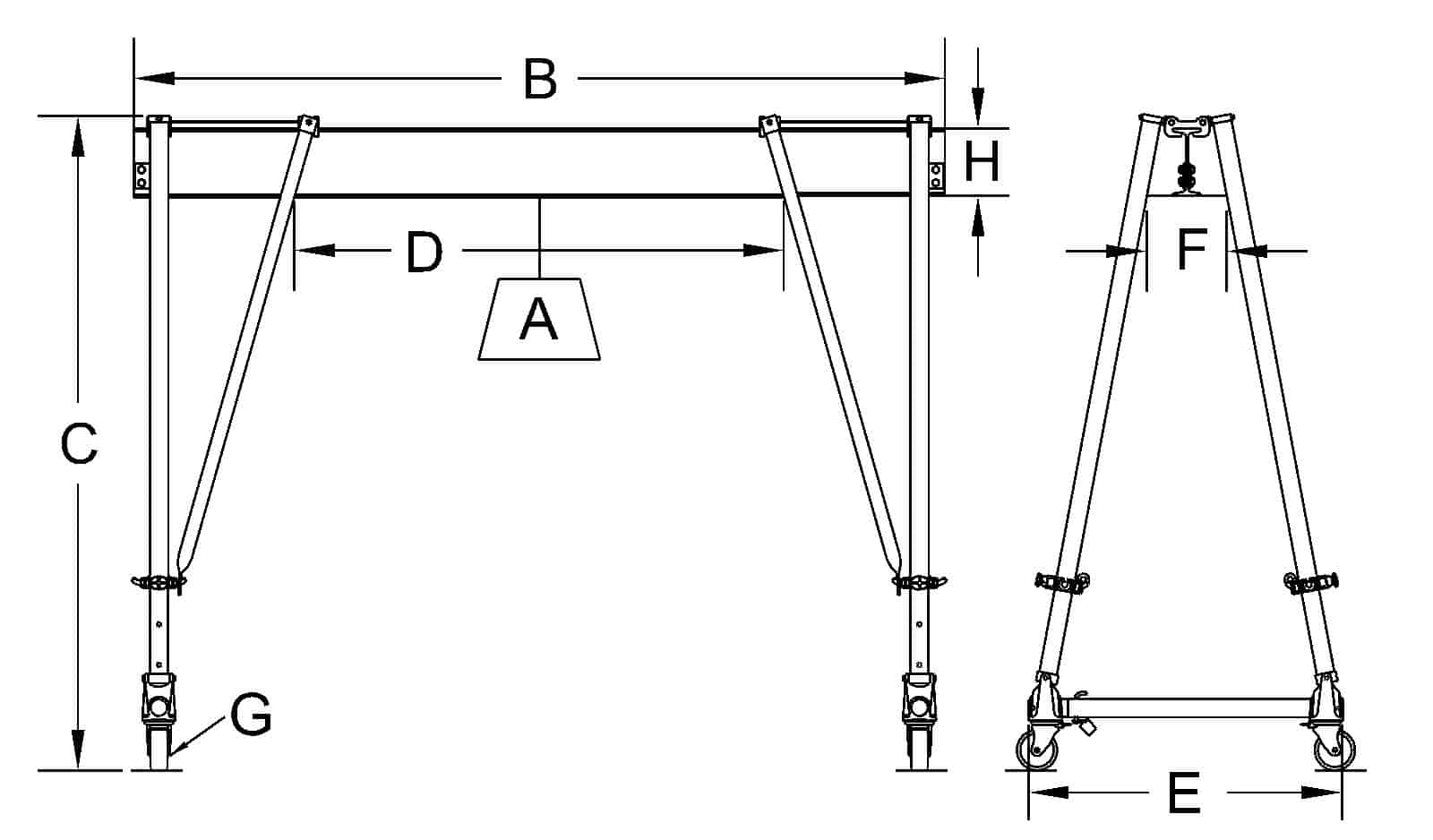

✓ 1-Ton (2,000 pound) capacity (A)

✓ 10′ Span (B)

✓ 8′ 10″ Clear Span (D)

✓ 6′ 9″ – 8′ 9″ Adjustable Height (C)

✓ 4′ 6″ Tread (E)

✓ 6″ Caster Diameter (F)

✓ 8″ I-Beam Depth (G)

✓ 194 Pounds Net Weight

Designed and manufactured in the United States

Completely portable

Easy to assemble, disassemble, transport, and store

Lightweight yet strong

Designed to roll under load

Most orders ship in 3 to 5 days.

Product Details

Key Features

Lightweight, Adjustable, and Portable

The lightweight and corrosion-resistant Thrifty™ Aluminum 1-ton adjustable-height gantry crane is one of our most popular product lines. It offers the greatest clear span (D) of any Wallace gantry crane and the aluminum design makes it an ideal combination of high lifting and reduced weight. This Thrifty comes with adjustable heights (C). It is easily assembled and disassembled for convenient portability.

- The Thrifty is built using our patented pinned-joint design resulting in a longer-lasting, better-fitting, more flexible crane that is quick and easy to assemble and disassemble.

- Strong rectangular posts and frames.

- Gussets for added strength eliminate the need for brace legs which allows for a greater clear span

- The exclusive Wallace I-beam support system aligns off-center loads to avoid distortion of the crane and trolley.

- Casters are equipped with a 4-position swivel lock. When locked 90 degrees with each other, they position the crane more firmly than a brake.

- Adjustable legs permit crane height adjustments in 6″ increments using spring-loaded bolts. You can raise the height of your crane so it goes over materials and equipment, lower it under low ceilings and doorways, or set legs at different heights when floors or terrains are uneven. It’s ideal for truck loading or from a dock to a floor or ground level to a mezzanine.

- Completely portable – many aluminum models can be hand-carried.

- Designed to roll under load.

Dimensional Drawing

Print / download A28-10AC dimensional drawing (PDF).

View I-Beam Flange Width Chart for Wallace Gantries.

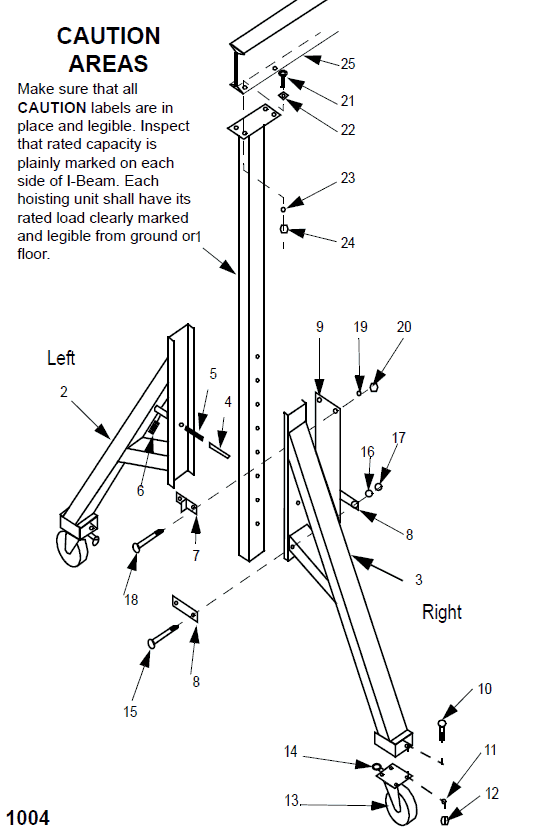

Parts List

| ITEM NO. | PART DESCRIPTION |

|---|---|

| 1 | POST |

| 2 | FRAME ASSEMBLY — LEFT |

| 3 | FRAME ASSEMBLY — RIGHT |

| 4 | PIN — HEIGHT ADJUSTMENT |

| 5 | SPRING — HEIGHT ADJUSTMENT |

| 6 | SPRING — PIN |

| 7 | UPPER BOLT PLATE |

| 8 | LOWER BOLT PLATE |

| 9 | STABILIZER PLATE |

| 10 | CAP SCREW — CASTER |

| 11 | LOCK WASHER (INTERNAL TOOTH) CASTER |

| 12 | HEX NUT — CASTER |

| 13 | CASTER |

| 14 | CASTER SWIVEL LOCK — (ATTACHED) |

| 15 | CAP SCREW — LOWER BOLT PLATE |

| 16 | LOCK WASHER — SPLIT |

| 17 | HEX NUT — LOWER BOLT PLATE |

| 18 | CAP SCREW — UPPER BOLT PLATE |

| 19 | LOCK WASHER — SPLIT |

| 20 | HEX NUT — UPPER BOLT PLATE |

| 21 | CAP SCREW |

| 22 | BEVEL WASHER |

| 23 | LOCK WASHER |

| 24 | HEX NUT |

| 25 | I-BEAM |

Note: There are alternate v-groove casters available for this crane.

Print / download a copy of the A28-10AC parts list and parts location diagram (PDF).

Parts Location Diagram

Wallace Thrifty Adjustable-Height Gantry Crane Parts Location Diagram

Print / download a copy of the parts list and parts location diagram (PDF).

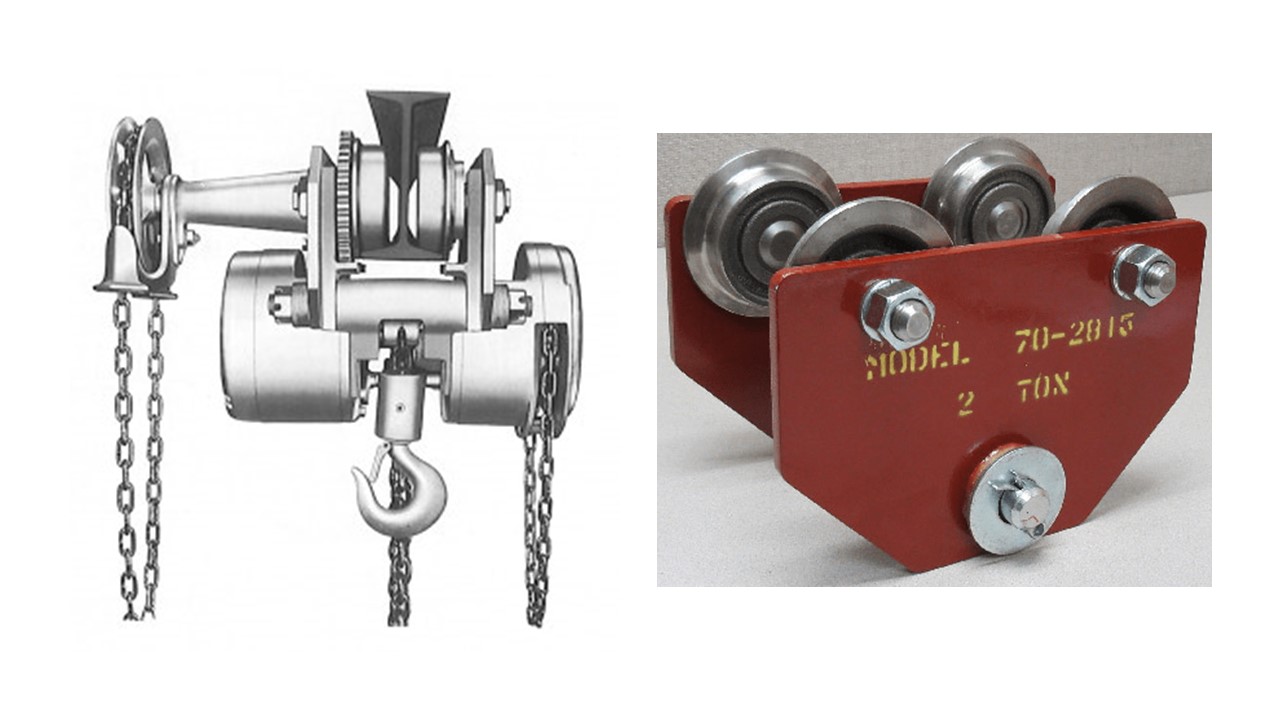

Optional Accessories

Available accessories include manual and electric trolleys and hoists as well as festooning kits to keep hoist, trolley, and power drive system cords up and out of the way. Cable ratchet kits to speed height adjustments are available for Thrifty crane models with 1/2-ton through 5-ton capacities.

Options for track mounting with V-groove casters and motorizing cranes are also available.

Assembly and Disassembly Instructions

Cautions

- Read and understand instructions before using this gantry.

- Inspect gantry thoroughly before using. See the Aluminum/Steel Thrifty Frame Assembly Instructions (Forms 386 and 387) Parts List for damaged or missing parts.

- Do not lift more than rated capacity.

- Center hoist over the load.

- Do not allow the load to swing or roll against any supporting members.

- When moving the gantry under load, push on the gantry, not the load. Be certain that the rolling surface is hard, level, clean, and smooth.

- Do not move the gantry over 50 feet per minute (1/2 m.p.h.).

- Not to be used for lifting or supporting humans.

Before You Begin

- Place parts on a flat surface, preferably on cardboard to keep small parts clean and organized.

- Select a clear area to assemble the crane. The work envelope should be at least as large as 2 times the leg length and wider than the beam. This clear area should be serviced by a crane or lifting device capable of lifting the entire weight of the completed crane. The lifting device must have sufficient height for the posts to be raised clear of the frames.

- Select tools for fastening the nuts and bolts.

- You will also need C-clamps to hold the trolley in place while the crane is assembled.

Print / download a PDF of detailed, step-by-step Aluminum/Steel Thrifty Frame Assembly Instructions (Forms 386 and 387) for the combined parts list and assembly instructions.

Safety Tag and Label Locations

Safety Tag Location

The following sketch shows the location of required safety tags on Wallace Tri-Adjustable Gantry Cranes. All locking pins or pins with a quick release must have a corresponding Tag 1969. Following the schematic below is a complete listing of all text found on all Labels and Tags on the Crane.

Print / download a PDF of the Tri-Adjustable Round-Tube Safety Tag and Label Locations Diagram.

Inspection Checklist (Form 504)

Instructions include:

- What to check for.

- How often to check.

- Frequent Inspection Checklist.

- Periodic Inspection Checklist.

View detailed Gantry Crane Inspection Checklist (Form 504).

Print / download a PDF copy of the checklist.

If you have questions or need assistance, please contact us.

Disclaimer

Please note this checklist was derived from company proprietary materials and (3) source documents including ANSI B30.17, CMAA Specification #74 Revised 1987, and OSHA 1910.179. As excerpts, the short form Wallace documents are intended to serve as general guidelines and are not to be considered the sole source when performing routine maintenance and inspection tasks.

Operating, Adjustment, and Inspection Instructions (Form 1004)

Instructions include:

- Inspecting Crane Before Moving and/or Each Day’s Use

- Positioning of Crane to Handle Loads

- Positioning of Casters

- General Safety Instructions for Crane Adjustments and Use

- Methods of Supporting Crane for Assembly

View detailed Thrifty Operating, Adjustment, and Inspection Instructions (Form 1004).

Print / download a PDF copy of the instructions.

Warranty and Disclaimer

Wallace product warranty and errors and omissions disclaimers can be found below.

They are also in the About section of this website and on the main Thrifty Aluminum Adjustable-Height 1 and 2-Ton Gantry Cranes page.

Engineering Specification

Gantry end frames shall be of aluminum rectangular tube construction manufactured to Wallace Cranes standards including, but not limited to, the following:

- Gantry shall be adjustable in height.

- Gantry shall have fixed tread.

- The aluminum alloy I-beam shall be American Standard and have a design deflection of no greater than l/450th of the span.

- The telescoping posts shall be adjustable in 6” increments when adjusting height. The posts shall have internal reinforcement as well as gussets welded to top plates.

- The main frames shall have a spring-loaded load-adjusting pin for adjusting/maintaining the height of the crane. Frames will be manufactured with custom-made channel for better fit with bolt and plate upon assembly.

- Gantry shall be equipped with four, 360-degree rotating, non-marking phenolic resin casters with 4-position swivel locks, at 90 degrees, to provide easy steering of crane by locking “lead” casters only, or to allow positioning of the crane more firmly than a brake by locking all four casters 90 degrees to each other. Casters shall be 6” in diameter.

- The model number to be provided shall be tested in accordance with Wallace Cranes specifications (A specific unit shipped is not tested; unless a Certificate of Test is ordered [additional charge applies]).

- Optional cable ratchet hoist kits for height adjustment are available for an additional charge. Please specify when ordering.

- Optional span adjustment kits on cranes up to 15’ I-beam spans are available for an additional charge. Must specify when ordering.

- Gantry is manufactured in accordance with our interpretation of ANSI B30.17 and U.S. OSHA, (Section 1910.179, revised January 1976), regulations at the time of manufacture.

Print / download a PDF version of the specification.

Related Products

Wallace also offers a Tri-Adjustable aluminum gantry crane in 1/2 to 3-ton capacities. These cranes have an adjustable height, span, and caster frame spread and weigh as little as 216 pounds.